Hello everyone, it's Leïla here to talk to you about a very important subject: inks in textile printing.

What is textile printing ink?

Textile printing ink is the essential product that allows you to transfer a durable and precise colour onto different fabrics. Whether cotton, synthetic fibres or more technical blends, each textile requires a suitable ink to guarantee resistance and quality of finish. Traditionally, textile printing relies on screen printing, a technique that offers excellent opacity, intense colours and optimal resistance to weathering, light and repeated machine washing.

The main components

1. Pigments: colour

These are what give the fabric its colour and visual intensity (black, red, blue, yellow, etc.). Their quality determines the fabric's resistance to UV rays and washing, as well as the vibrancy of the final result.

2. Binder: adhesion to fabrics

The binder fixes the pigments to the material (cotton, polyester or blends). It determines the durability of the print, the comfort of wear and the flexibility of the fabric after customisation.

3. Liquid base: shaping

This carries the pigments and makes the ink usable in the workshop. In conventional inks, it often contains solvents; in eco-friendly alternatives, it is based on more responsible formulations.

4. Additives: performance

These adjust the final properties:

- thickening agents (ink stability in screen printing),

- anti-foaming agents (even surface),

- components to improve wash resistance,

- or special additives to create effects (3D puff, fluorescent, reflective).

The different types of textile inks

Plastisol inks

Plastisol inks, which are still widely used, are popular because they are easy to apply and competitively priced. However, they are based on PVC and solvents, which is not really in line with eco-responsibility. At Inkoo, we banned them a long time ago because we are committed to offering the most responsible textile customisation possible.

Water-based inks

Water-based inks have become an essential alternative. More environmentally friendly, they offer a soft feel and are ideal for cotton fabrics. They are perfect for professional customisation where comfort and durability are required.

Other technologies (discharge, UV, etc.)

There are also discharge inks, which remove the original colour from a dark textile in order to print a new colour, and UV inks, which are used for specific purposes such as technical sportswear or safety textiles. They react to ultraviolet light to create a fluorescent effect, ideal for markings that are visible in the dark or under black light.

Why choose eco-friendly textile printing ink?

A response to current demand

Consumers and businesses alike are increasingly mindful of the environmental impact of the products they buy. In the textile industry, this translates into high expectations in terms of sustainability, water conservation and natural fibres such as cotton.

In printing, choosing a water-based, solvent-free ink makes it possible to offer textiles that meet this new requirement: intense colours that are resistant to washing, while reducing the pollution associated with traditional inks.

This market development is not just a trend: it is now a key criterion for customers looking for products that are both attractive and responsible.

A choice aligned with certifications

Choosing eco-friendly textile marking ink also guarantees compliance with the industry's most recognised standards and labels.

- GOTS (Global Organic Textile Standard): requires the use of water-based inks without harmful substances for organic fabrics.

- Oeko-Tex Standard 100: certifies the absence of hazardous chemicals in inks and printed textiles.

- Fair Wear and other initiatives: promote a safer process for workers by limiting their exposure to toxic solvents and additives.

By complying with these certifications, brands benefit from two advantages:

1. A guarantee of quality and safety for their customers.

2. An enhancement of their brand image in terms of sustainability, an absolutely essential criterion in today's professional textile markets.

Comparison: conventional inks vs eco-friendly inks

Impact of conventional inks (harmful substances, pollution and risks)

Traditional inks are often attractive because of their competitive price and ease of use. But behind this immediate advantage lie several limitations:

- Limited durability: some inks eventually fade or even crack after washing, which significantly reduces the lifespan of customised textiles.

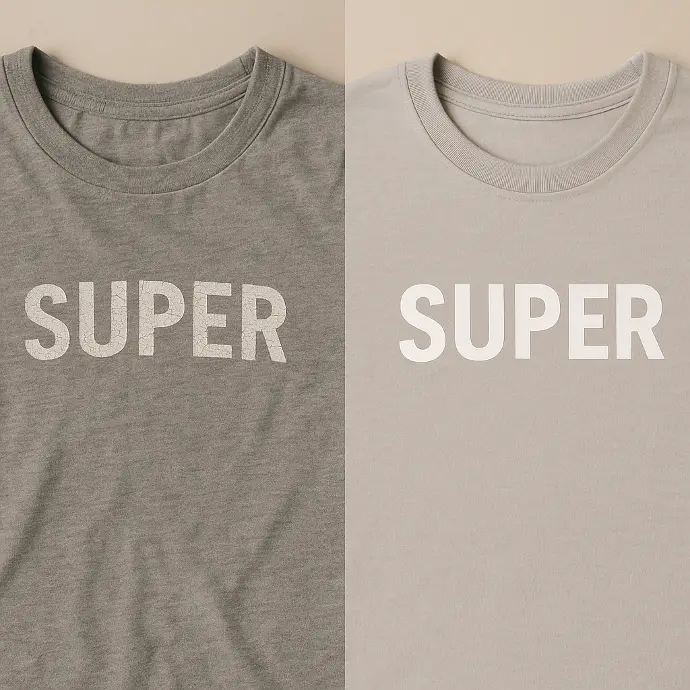

- Questionable comfort: a thicker, even plasticised finish that stiffens the fabric. On a lightweight T-shirt or soft cotton, the difference is clear.

- Hindered innovation: these inks are ill-suited to new consumer expectations (more technical fabrics, demands for colour intensity, premium finishes).

Benefits of eco-friendly inks (reduced impact, added value)

Responsible alternatives are not only ‘less polluting’: they also provide real added value for professionals and their customers:

- Perceived superior quality: a finer finish, bright colours and a much finer, softer feel that does not alter the thickness of the T-shirt and reinforces a brand's premium image.

- Versatility: suitable for cotton but also for more modern blends, they are better suited to a variety of needs (fashion, sports, corporate).

- Customer confidence: being able to associate a personalised garment with recognised labels such as GOTS or Fair Wear is becoming a strong selling point.

- Long-term profitability: fewer returns due to prints that wear out quickly, and increased customer satisfaction that improves loyalty.

Eco-friendly textile printing ink: which one to choose and for which applications?