Hello everyone, this is Leïla from Inkoo, here to talk about an often underestimated but essential element when choosing a fabric: fabric weight.

Whether you’re creating your merchandising, launching a clothing collection, or simply selecting the right cotton for a specific project, understanding fabric weight will help you better anticipate the quality, durability, and comfort of your textile.

If you are not interested in the weight of the clothing but want to find out more about the fit and cuts of our garments, I wrote an article about it.

Key Takeaways

- Grammage = fabric weight (g/m²) — a key measure of thickness, density, and durability.

- Match grammage to use: Light (120–150 g/m²) for summer wear, Medium (180–220 g/m²) for hoodies/polos, Heavy (300+ g/m²) for jackets or tote bags.

- Not the same as density: Weave and fiber type can make fabrics with the same grammage feel very different.

- Affects customization: Screen printing, DTG, and DTF each work best with specific grammage ranges.

- Balance comfort and durability: Heavier isn’t always better—choose based on intended use.

What is fabric weight?

It refers to the weight of a fabric expressed in grams per square meter (g/m²). It’s a key indicator of its thickness, density, and strength.

Whether you’re planning a garment manufacturing project or printing on a textile product, knowing its weight will help you assess the quality and longevity of the fabric before you even touch it.

Confused about which textile for which uses? We made a guide about it.

Definition and importance of fabric weight

A heavier fabric generally has a higher density, which impacts its use and resistance. For example:

- Light cotton (120–150 g/m²) is ideal for summer shirts or t-shirts.

- Medium weight (180–220 g/m²) suits sweatshirts or polos.

- High weight (300 g/m² and above) is preferred for jackets, upholstery, or heavy-duty tote bags.

The thickness of the fabric helps anticipate comfort, drape, and insulation, depending on the weave and fibers used.

Fabric weight vs. density: What’s the difference?

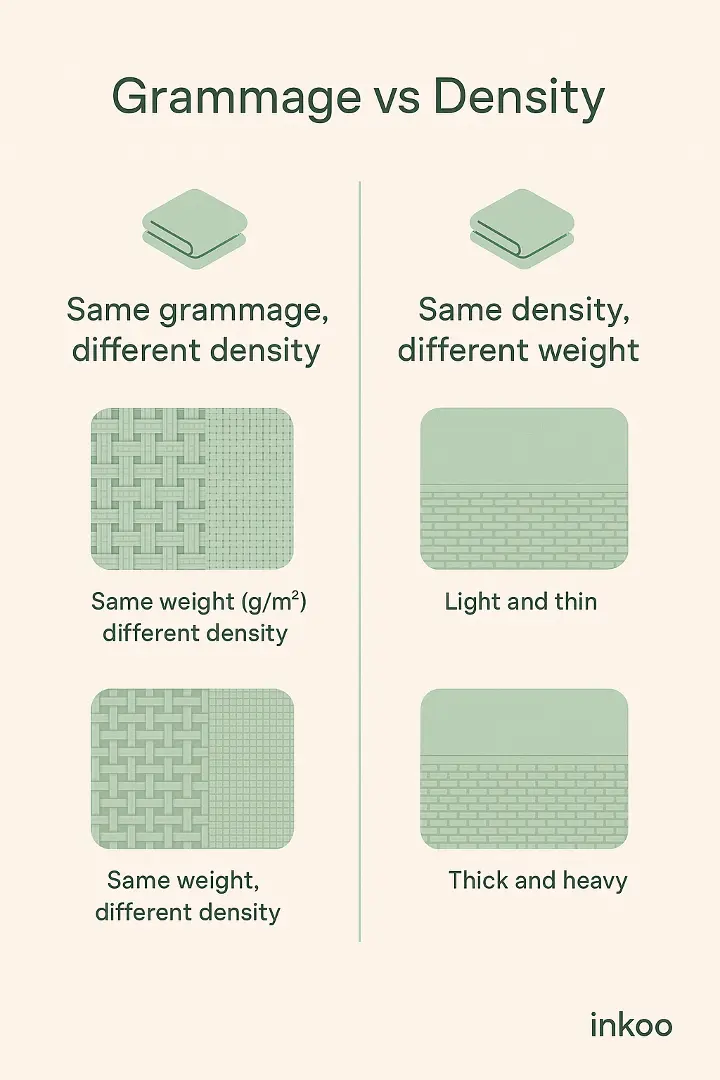

Though very similar and often confused, fabric weight and density are not the same:

- Fabric weight: the weight of the fabric over a given surface (g/m²).

- Density: the ratio between weight and volume, influenced by the type of weave and yarn thickness. Two fabrics can have the same weight but different compactness depending on their weave structure.

Influence of composition and weave

Weight alone doesn’t give the full picture of a fabric. Composition plays a major role: a 200 g/m² cotton will not drape the same way as a 200 g/m² cotton/polyester blend. The weave type also affects the feel: a tight canvas will seem denser and more resistant than a looser jersey, even at the same weight.

For a project that requires both comfort and durability, you must consider weight, composition, and weave together.

How to determine fabric weight

To measure a fabric’s weight, take a sample of known surface area (e.g., 10x10 cm), weigh it, then extrapolate to grams per square meter. Some labels indicate the weight directly, especially for cotton or linen items intended for garment making.

Common techniques for measuring g/m²

- Precision scale: for standard samples.

- Special circular cutter: used in the industry to always obtain the same surface for weighing.

- Indirect measurement: calculated from technical data provided by the manufacturer.

Using fabric weight for different types of textiles

- Lightweight garments: low weight for summer comfort.

- Sportswear: medium weight for flexibility and resistance.

- Workwear & outdoor: heavy weight for protection and durability.

- Home textiles: high weight for wear resistance.

Fabric weight & customization techniques

Thickness also influences how a fabric reacts to customization techniques:

- Screen printing: a fabric that’s too light may let ink pass through or distort during printing, affecting visual precision.

- DTG (Direct-to-Garment): medium to high weight in cotton offers better absorption and more vivid colors.

- DTF: denser fabrics allow better adhesive penetration, improving wash resistance.

Choosing the right weight for your chosen technique is essential to ensure the quality and durability of your customized clothing.

How does fabric weight influence quality?

An appropriate fabric weight ensures:

- Durability: heavier fabrics better resist wear.

- Compactness: better structure and less deformation after washing.

- Strength: better suited to intensive use.

Impact of weight on durability

Heavier fabrics, though sometimes less supple, often last longer. For projects needing daily use (tote bags, aprons, work trousers), a high g/m² is a sign of sturdiness.

Influence of weight on comfort and insulation

Fabric thickness also affects warmth and thermal comfort:

- Lightweight → breathable and pleasant in summer.

- Heavyweight → insulating and protective in winter.

Common misconceptions

Many believe that heavier always means better. Not true: a very heavy t-shirt can be uncomfortable in summer, while a too-thin tote bag might tear quickly. The goal is to find the right balance between weight, intended use, and resistance so the fabric fits your project perfectly.

Over misconceptions, there are a lot of mistakes to avoid in textile printing, so be careful before starting a production.

Conclusion

Fabric thickness is more than just a number — it’s a key indicator that influences the quality, durability, and comfort of your clothing and accessories. Whether you opt for a light, breathable fabric or a thicker, more resistant one, the right choice always depends on your use and project.

At INKOO, we help you find the ideal fabric weight tailored to your needs and brand image, combining style, strength, and high-quality weaving. 📩

Need advice or a sample? Contact us and we’ll guide you toward the perfect textile for your creations.

Understanding Fabric Weight to Choose the Right Material